MBBR

MBBR

- Detail

- Parameters

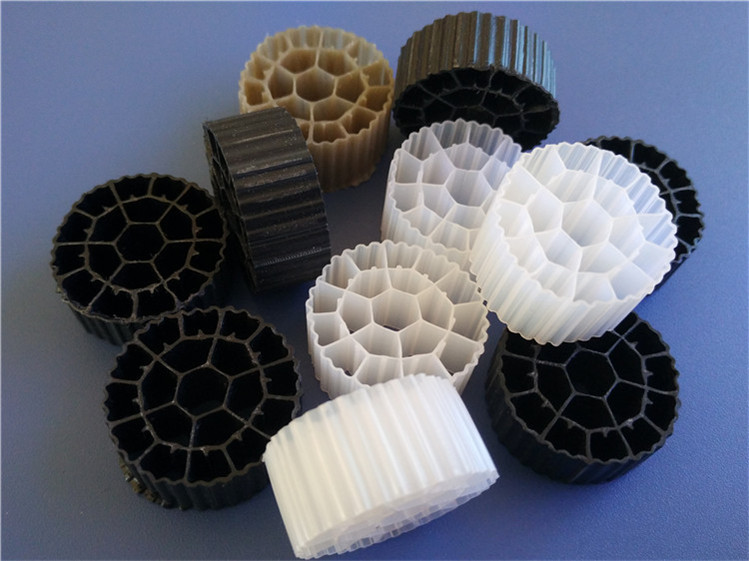

The MBBR technology combines the advantages of both conventional fluidized bed and biological contact oxidation.It relies on the aeration in the aeration tank and the lifting effect of the waterflow to make the carrier in a fluidized state, and then form a suspension,It forms the growing activated sludge and the attached biofilm and the microorganism amount is huge.

The main features:

1. High processing load;

2.It requires smaller tank, which reduces infrastructure investment;

3. no sludge backflow and backwashing system investment is reduced.

4.low sludge volumn and reduces sludge disposal cost.

5. Easy operation and installation.

Our MBBR Unique Features:

1.Use biological hydrophilic polymer material which can adsorpt more pollutant.

2. Use biologically active substances.

4.The introduction of active calcium in biofiller.It significantly modified the mechanical properties of the polymer filler, especially impact strength and toughness;

5. In order to further improve the dispersibility of the additive and prevent agglomeration, the active calcium and barium ferrite magnetic powders are chemically coated and modified, and then mixed and processed with other components. The modified inorganic powder material is evenly distributed inside and on the surface of the filler, so that the product performance is more stable.

So, our MBBR has 10%~30% higher COD removal rate and biofilm forming time is 3-6 days shorter than others.